Shot peening will result in higher compressive stresses

Shot-peening is very popular today as a method to increase the compressive stresses in and just below the surface. By that, the component can with-stand higher loads and still keep the fatigue life.

This could also mean that we can reduce weight and size of the component, and keep the same load. Lower weight means lower energy consumption, which will result in lower emissions and less carbon foot-print.

The surface of the component is bombarded by small balls or cut wire, always under controlled power, intensity, and coverage.

Every small ball that hits the surface will act as a small hammer that will make an indent or crater. Under the indent is created a volume with higher compressive stresses.

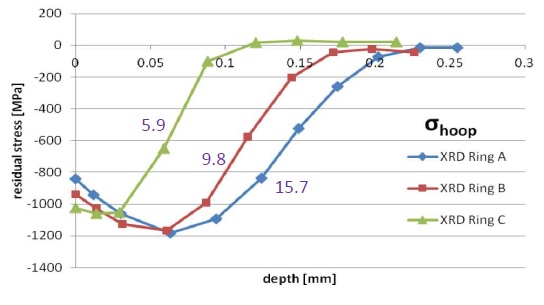

The figure shows depth profiles from residual stress measurements using X-ray diffraction, by three components of high strength steel. The components have been shot peened with different intensities. Resulting in different residual stress profiles below the surface.

(Rickert et al; “Residual stress measurements of shot-peened steel rings by Barkhausen noise, ESPI hole-drilling and X-ray diffraction”, Proc. of ECRS9, 2014)